The PI Dr. Ben-Tzvi’s Robotics and Mechatronics Lab (RML) at Virginia Tech (VT) is a well-established and rapidly expanding 3,500 square foot research center on VT’s main Blacksburg campus located on the ground level of Randolph Hall at 460 Old Turner Street. The lab is currently divided into four major areas/rooms, including an office area with students’ desks, a prototype integration area, a workshop area with fabrication facilities and storage, and a conference room for group meetings and discussions. This lab is available for hosting all the research activities related to the proposed work. Currently, the lab accommodates twenty three workstations for researchers with personal storage at each station. It also contains storage cabinets for supplies, and tables/carts on which researchers can integrate systems and conduct experiments. Each workstation is equipped with quad-core Dell computers.

Computers & software

RML has 25 Dell quad-core (3.3 GHz, 8 GB RAM, Windows 7 64-bit) desktop computers for general modeling, simulations, and day-to-day use, and 5 Dell quadcore (2 GHz, 4 GB RAM, Windows 7 64-bit) laptop computers for mobile and off-site use. For more complicated simulations and analyses, the lab has a multi-purpose 12-core 64-bit (2.4 GHz, 16 GB RAM) computer station operating Windows 7 on a hard-drive of 2 Terabytes. The computers operate Linux and Windows platforms and are loaded with licensed software necessary for our research needs, including Matlab, Mathematica, PENBMI from the TOMLAB, C++ and C development environments, MathCAD, Maple, MSC ADAMS and related Toolkits, Abaqus, SolidWorks, ProEngineer, ANSYS, and LabView. Additional software is also available when needed from VT's College of Engineering license server. Furthermore, the lab is located on the same with the machine shop. In addition to the Design, Instructional and computer Labs, computational clusters for even more advanced simulations are available.

Major Equipment

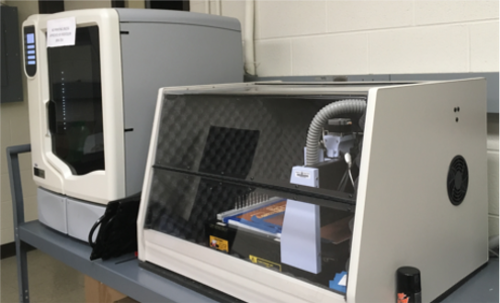

Within RML, the PI has the necessary equipment and resources to carry out experimental work in robotics from preliminary mechanical, electrical and software design, to fabrication/assembly and integration, to full-scale implementation and testing. Specific manufacturing equipment in the lab

includes: 1) a private Stratasys uPrint SE Plus 3D printer for manufacturing plastic components for prototypes, 2) a Granite 1324 IMAX Metric 3-in-1 mill/lathe/drill press for quickly manufacturing and modifying components in the lab when necessary, 3) an Othermill CNC Mill for manufacturing small-scale metal components, and 4) a Full Spectrum P2416+ laser cutter for manufacturing laser cut plastic components.

Available electrical equipment in RML includes a variety of diagnostics and measurement equipment, including cameras, data acquisition systems, signal spectrum analyzers, signal generators, power supplies, multi-meters and oscilloscopes. The PI also has an ElevenLab Printed Circuit Board (PCB) prototyping machine to fabricate electromechanical components, as well as soldering and spot welding systems. This equipment enables the full design, prototyping and integration of electrical subsystems.

In terms of existing robotic systems, RML currently houses several cable and rod-driven continuum robotic test platforms, several serpentine tail prototypes (universal-spatial robotic tail, roll-revolute-revolute robotic tail, discrete modular tail), a prototype spatial tracking system, a fully integrated hybrid mobile robot, several haptic glove prototype systems, a Novit Falcon haptic interface, a Geomatic Touch haptic devices, several docking mechanisms for modular and reconfigurable robotics, a prototype spatial tracking system, an RC helicopter instrumented for ship air wake measurement.

Other Resources

Machine Shop

RML is located on the same floor as the Mechanical Engineering Department‘s Machine Shop. The shop contains a variety of equipment for general and specialized machining, including computer numerical control (CNC) lathes, CNC milling machines, drill presses, a laser cutter and a rapid prototyper. The machine shop staff is available to assist in manufacturing at no direct cost other than materials. The machine shop will be used for manufacturing experimental hardware for the prototype work and is fully available for the research project.

Vicon Motion Capture System

On VT’s main campus the PI and his students have access to a Motion Capture facility, consisting of 14 Vicon T160 cameras for high-speed (120 Hz at full 16 MP resolution) motion capture if necessary for testing and characterizing various integrated robotic systems.

Library

Virginia Tech provides its faculty and students access to a wide cross-section of high-quality journals and conference proceedings, allowing the students to stay current on state-of-the-art advances. Any book or paper to which students do not have access may be easily ordered through the Interlibrary Loan service and digitally or physically delivered.

The Frith Design Laboratory (Frith Lab)

The lab features over $150,000 worth of equipment that any student can use for their research work. It features a Tensile/Compression Materials Testing machine, 3-D printers, laser engraver, CNC router, and drill press, along with various hand tools, housed in toolboxes available for checkout. The tools can be used for projects assigned in engineering classes, and students are encouraged to come and use the lab for their own research work.

Department of Mechanical Engineering CAD Lab

This lab provides high-performance computing for interactive CAD/CAM/CAE education and research utilizing a suite of high performance workstations. Pertinent software includes ANSYS, AutoCAD, all Autodesk software offerings, CATIA, FLUENT, LabView, NX, Pro/Engineer, SolidWorks, and many other industry standard CAD software.